FX and TWIN Belt scales

FX and TWIN scales were designed for weighing bulk products inthe extractive, mineral, cement, fertilizer or phosphates production, agri-industry, sugar refinery, timber, recycling industry market sectors and other activities using belt conveyors.

The scales can be installed in a new conveyor or can easily replace an existing conveyor roller station. These continuous weighing infrastructures can be combined with PRECIA MOLENI 410 BS electronics.

The accuracy of these scales can be from +/- 0.5 % to +/- 1 % for a conveyor having a belt width up to 1200 mm for FX model and beyond for TWIN model.

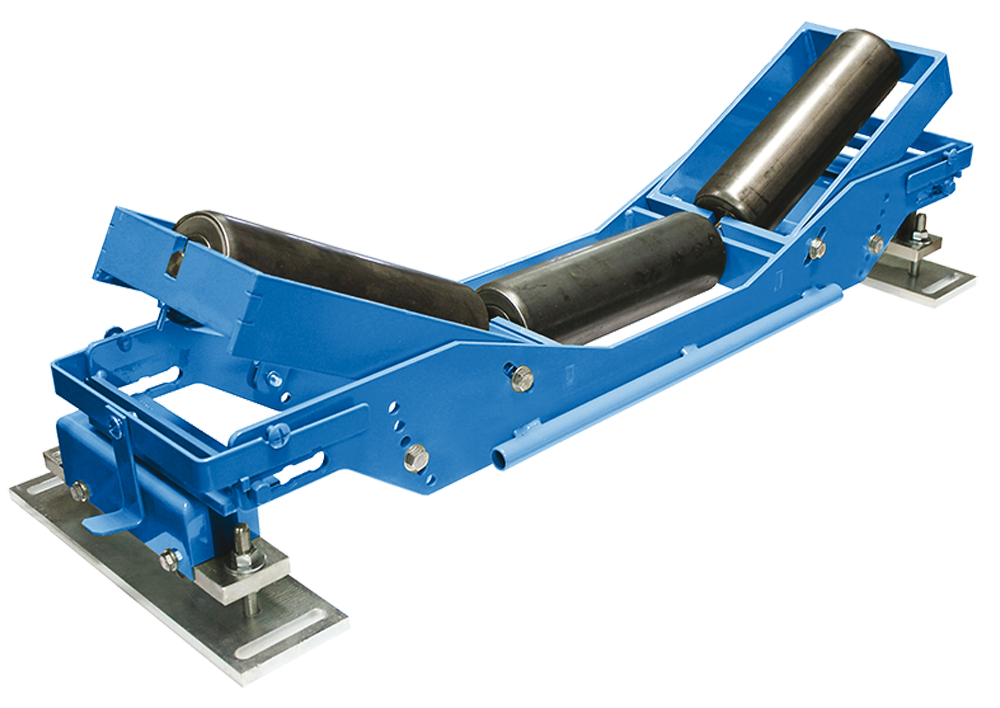

The FX / TWIN scales is composed of:

• 2 identical strain gauge sensor blocks equipped with an integrated overload stop and a clamping system for transport.The FX blocks have a built-in adjustment device allowing adjusting the weighing trough height with respect to theconveyor troughs.

• 1 specific roller station manufactured according to the current conveyor section to be equipped. For ISO 53300 and DIN 53301 standard conveyors, this station is equipped with an adjustment device allowing selecting the trough angle between 20° and 45° depending on the one on the conveyor. Whatever the conveyor profile, a station consists of:

• Screws incorporated into the weighing trough allowing height adjustment of the 3 rollers and the fine alignment ofeach roller with respect to those of the upstream and downstream stations. This device allows carrying out a realweighing plan and eliminate measuring disturbances related to banding.

• Two standard weight brackets allow suspending thestandard weights easily and carrying out a calibration safely because the brackets are outside of the conveyor.-A protective tube passes the sensor cable to the junctionbox or weight transmitter.

The FX / TWIN totalizing scales can be installed on any type of trough belt conveyor with a heavy or light frame, in profiles, shell, latticeor tubular.